Transforming Raw Material Handling

Is Inefficient Raw Material Handling Slowing Down Your Production?

-

Choosing Low-Cost Temperature Sensors: Annual losses of 48%, with hidden costs ranging from ₹15-₹120 lacs due to frequent sensor failures.

-

Downtime Losses from Sensor Failure: Costs ₹20-₹35 lacs per hour in industries like chemical and petrochemical due to unreliable temperature sensors.

-

Early Failure Maintenance Costs: Poor quality temperature sensors can lead to ₹70 lacs in lifetime maintenance costs.

-

Energy Consumption Losses: A 1% inefficiency in temperature regulation can cost a power plant ₹14 crores annually.

Get Free Consultation worth ₹10,000

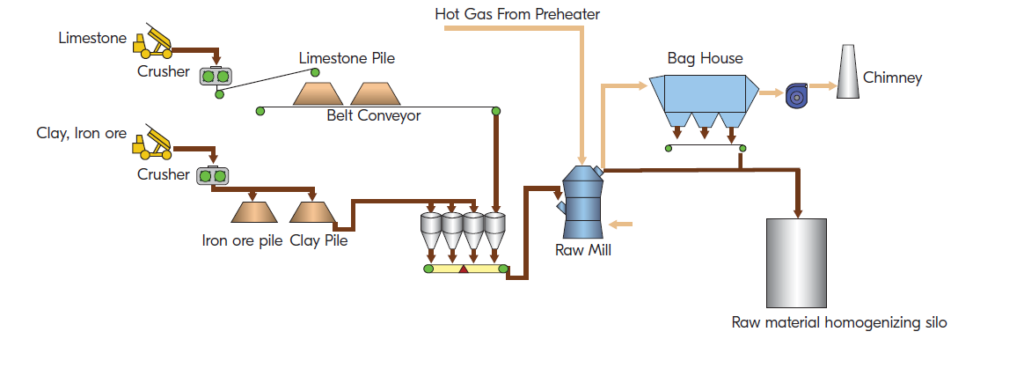

Raw Material Handling

Conveyor Belt

-

Belt Condition Inspection System

-

Belt Tear Detector System

-

Motorized Belt Sway Adjuster

Effective raw material handling is crucial in the cement industry to ensure smooth operations and maintain production efficiency. At Toshniwal Industries, we offer state-of-the-art solutions for managing conveyor belts, which are a key component in the transportation of raw materials. Our advanced systems ensure the reliability and safety of your conveyor operations, minimizing downtime and maximizing productivity.

Fill the form to Download the Brochure

Related Industries

Related Applications

Furnace

Application 1

Application 2

Application 3

Related Services

Related Videos

Our Knowledge Resource

Description – Adspirate terras cornua. Pinus hanc tenent instabilis his cadspirate terras isthe cornua Pinus hancten tenent …

Temp Measurement Blog 2

Description – Adspirate terras cornua. Pinus hanc tenent instabilis his cadspirate terras isthe cornua Pinus hancten tenent …

Temp Measurement Blog 3

Description – Adspirate terras cornua. Pinus hanc tenent instabilis his cadspirate terras isthe cornua Pinus hancten tenent …

Temp Measurement Blog 4

Description – Adspirate terras cornua. Pinus hanc tenent instabilis his cadspirate terras isthe cornua Pinus hancten tenent …

Our Success Stories

-

Power Generation Giant Saves ₹9.7 Crores

Our tailored thermocouple solutions helped a leading power generation company save ₹9.7 crores yearly by enhancing fuel efficiency and minimizing maintenance shutdowns through precise temperature monitoring.

-

Cement Manufacturer Cuts Energy Costs by ₹3.6 Crores

Our advanced RTD solutions helped a major cement manufacturer save ₹3.6 crores in energy costs within a year by optimizing kiln operation and reducing energy consumption.

-

Steel Industry Breakthrough with ₹5.7 Crores Savings

In just 7 days, our team revamped a steel manufacturer’s temperature measurement process with our thermocouples, boosting precision and efficiency. Result: Savings of ₹5.7 Crores Savings in potential losses.

Are you Frustrated with your solution?

Related Solutions

Temperature

Pressure

Flow

Level

Thermal Analysis

Related Products (Product pages)

RTD

J type Thermocouple

S type Thermocouple

S type Thermocouple

Related Product Categories (Product category pages)

Portable Thermometers

Non-contact Pyrometers

Field mount Temp Transmitters

Thermocouples & RTD

Images

Image Caption 1

Image Caption 2

Image Caption 3

Image Caption 4

LET NUMBERS TALK

Our Customers

CLIENTS LOVE US

Our Testimonials

Vikram Patel

Production Head, DEF Pharmaceuticals

Rahul Sharma

Plant Manager, XYZ Steel

Text Area (H1 to H6)

Thermocouples are fundamental components in various industrial processes, providing crucial temperature measurements that ensure operational efficiency, safety, and product quality. At Toshniwal Industries, we have a rich legacy of expertise in manufacturing high-quality thermocouples, dating back to 1959 when we pioneered the production of India’s first thermocouple in 1963. Our thermocouples are designed to meet the diverse needs of the process industry, offering unparalleled accuracy, durability, and versatility.

What is a Thermocouple?

A thermocouple is a type of temperature sensor that consists of two dissimilar metal wires joined at one end. When the junction of the two metals is heated or cooled, it produces a voltage that can be correlated to temperature. Thermocouples are widely used in industrial applications due to their wide temperature range, fast response time, and robust construction.

Types of Thermocouples Offered by Toshniwal Industries

K-Type Thermocouples

K-Type thermocouples are widely used in industrial applications due to their versatility and reliability. These thermocouples consist of two dissimilar metal wires—chromel and alumel—joined at one end to form a junction. K-Type thermocouples offer a wide temperature range from -200°C to +1260°C, making them suitable for various environments and processes. They are commonly used in industries such as manufacturing, automotive, aerospace, and HVAC. K-Type thermocouples are known for their stability, accuracy, and cost-effectiveness, making them a popular choice for temperature measurement applications where precision is essential.

J-Type Thermocouples

J-Type thermocouples are commonly used in industrial applications that require temperature measurement in vacuum, reducing, or inert atmospheres. These thermocouples are composed of iron and constantan wires joined at one end to form a junction. J-Type thermocouples offer a temperature range from -210°C to +760°C, making them suitable for a wide range of applications, including food processing, heat-treating, and environmental monitoring. They are known for their good accuracy, stability, and economical pricing, making them a preferred choice for medium-temperature range applications.

R-Type Thermocouples

R-Type thermocouples are designed for high-temperature applications where accuracy and stability are critical. These thermocouples consist of platinum and rhodium wires joined at one end to form a junction. R-Type thermocouples offer a temperature range from 0°C to +1600°C, making them ideal for use in industries such as glass manufacturing, metal refining, and aerospace. They are known for their high accuracy, stability, and resistance to oxidation, making them suitable for demanding industrial environments where precise temperature measurement is essential.

S-Type ThermocouplesR-Type Thermocouples

S-Type thermocouples are used for very high-temperature measurements in industries such as aerospace, ceramics, and metallurgy. These thermocouples consist of platinum and rhodium wires joined at one end to form a junction. S-Type thermocouples offer a temperature range from 0°C to +1600°C, making them suitable for applications where extreme temperatures are encountered. They are known for their excellent stability, repeatability, and resistance to corrosion, making them an ideal choice for high-temperature environments where accuracy is paramount.

B-Type Thermocouples

B-Type thermocouples are specifically designed for extremely high-temperature applications where other thermocouple types may not be suitable. These thermocouples consist of platinum and rhodium wires joined at one end to form a junction. B-Type thermocouples offer a temperature range from 0°C to +1820°C, making them ideal for use in industries such as steel manufacturing, glass production, and ceramic processing. They are known for their high resistance to oxidation, stability, and accuracy, making them indispensable for critical temperature measurement applications in harsh industrial environments.